- BRNN

- BRI News

- BRNN News

- Database

Official Documents Polices and Regulations

Inter-government Documents International Cooperation BRI Countries

Business Guide Economic Data BRI Data

Trade

Investment Projects Latest projects

Cases - Content Pool

Technicians are debugging an ultra-large-diameter shield tunneling machine bound for export to Australia at the general assembly workshop of China Railway Engineering Equipment Group Co., Ltd. in Zhengzhou, central China's Henan province, April 2, 2025. (Photo by Qiu Xinsheng/People's Daily Online)

In Zhengzhou, central China's Henan province, a shield tunneling machine with a diameter of 15.7 meters rolled off the production line, bound for export to Australia. This milestone marks the largest-diameter shield tunneling machine China has ever exported, underscoring the country's growing strength in the field of tunnel boring technology.

Meanwhile, in Shanghai's Chongming district, a Chinese domestically developed "Linghang" shield tunneling machine burrowed its way underground and reached the middle of the Yangtze River, remotely controlled by engineers.

Shield tunneling machines, formally known as tunnel boring machines (TBMs), are hailed as the "king of construction machinery" due to their immense scale and complexity. Once limited to horizontal excavation, today's Chinese-developed TBMs can operate in multiple orientations - including vertical, inclined, and curved trajectories - earning the nickname "transformers" for their adaptability and precision.

In September last year, a TBM named "Yongning" became the world's first large-diameter machine capable of climbing steep gradients. It successfully excavated an inclined shaft at the Luoning Pumped Storage Power Station in Henan province. The shaft, nearly 873 meters long with a slope of 38.742 degrees, had posed a significant technical challenge. "Yongning" conquered the slope with ease, marking a major leap in tunneling capabilities and improving overall construction efficiency.

The "Yongning" TBM was developed by China Railway Engineering Equipment Group Co., Ltd. (CREG), which has established multiple R&D teams to support application-specific innovation. The teams have enhanced TBMs to dig in various cross-sectional shapes - including circular, square, horseshoe, and elliptical - allowing for broader use across sectors such as water conservancy, hydropower, mining, urban infrastructure, and underground parking structures.

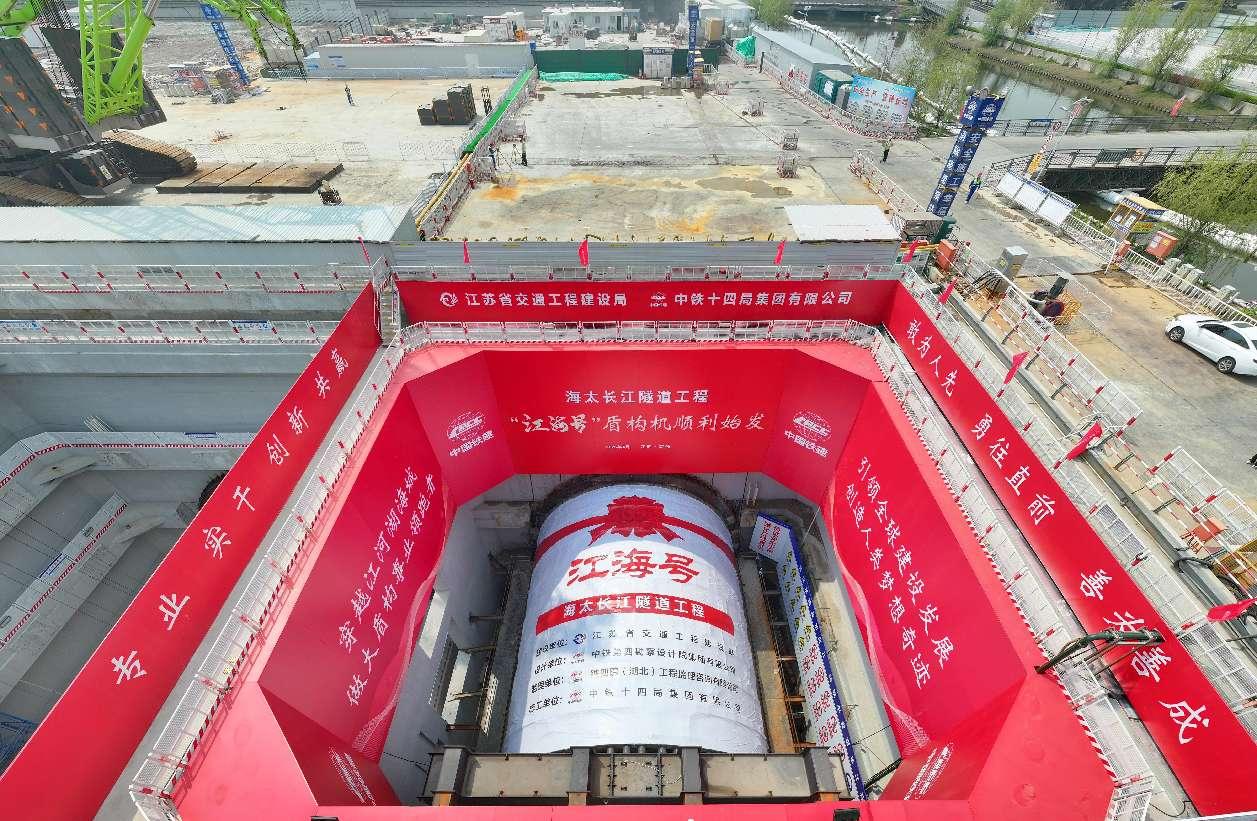

In October 2024, China unveiled the "Jianghai" TBM with a record-breaking diameter exceeding 16.6 meters, the largest ever developed domestically.

The Chinese-made ultra-large-diameter shield tunneling machine "Jianghai" is commissioned for the construction of "Haitai Yangtze River Tunnel," the world's longest underwater highway TBM tunnel, in east China's Jiangsu province. (Photo by Xu Congjun/People's Daily Online)

What drives the trend toward increasingly larger TBMs?

According to Chen Jian, a TBM expert at China Railway 14th Bureau Group Co., Ltd., the answer lies in greater cost-efficiency. Ultra-large TBMs enable the construction of single super-sized tunnels that can replace two traditional parallel tunnels, conserving underground space. Moreover, tunnels over 15 meters in diameter can also accommodate multi-layered infrastructure, such as roadways, rail transit, and utility corridors, within a single excavation.

However, with greater size comes increased technical complexity.

"Once the diameter exceeds 15 meters, the risks associated with unstable geological conditions increase exponentially, demanding higher levels of structural integrity, precision control, and material fatigue resistance," said He Fei, deputy head of the CREG technology center.

Back in October 2017, China's first domestically developed 15-meter-class slurry balance TBM, "China Railway 306," successfully rolled off the line, breaking the longstanding foreign monopoly in this field.

Since then, China has successively rolled out the 15.8-meter "Chunfeng," the 16.07-meter "Jinghua," and now the 16.6-meter-plus "Jianghai," surpassing its own benchmarks and establishing a fully integrated domestic industrial chain for ultra-large TBM production.

Today, Chinese-manufactured TBMs account for nearly 70 percent of the global market. As innovation continues, Chinese engineers are striving to make them both smarter and more environmentally sustainable.

Inside the cabin of the "Linghang" TBM, a dashboard displays real-time data on the machine's operating status. Human intervention is minimal, as the machine runs autonomously, guided by an advanced visual recognition and intelligent control system.

"In the past, TBM excavation was akin to working blind - geological uncertainties posed serious safety risks," said Liao Zhaojin, chief designer of the "Linghang" TBM.

Equipped with a cutting-edge geological forecasting system, "Linghang" can accurately detect geological conditions 10 to 40 meters in front of the cutterhead. Its intelligent sensing system continuously analyzes real-time conditions, enhancing both safety and accuracy. The TBM's AI-driven control system enables it to make autonomous decisions with millimeter-level precision.

Environmental sustainability is also a major priority. On July 23, 2024, "the China Railway 1237," the world's first green TBM, was successfully launched.

"What defines a green TBM is its ability to optimize energy use," explained Cao Shulei, chief designer of the machine. "We've equipped the machine with an intelligent system that automatically manages the various subsystems during tunneling to optimize both efficiency and energy consumption, achieving energy savings and reduced emissions."

The machine has since been exported to Italy, where it is being used for high-speed rail tunnel construction in Sicily - a sign of international recognition for China's green TBM technology.

Tel:86-10-65363107, 86-10-65368220, 86-10-65363106